Our Green Policies

Inner Traditions • Bear & Company is a leading publisher of books on indigenous cultures, perennial philosophy, visionary art, ancient wisdom, spiritual traditions, holistic healing, and self-development. From our founding in 1975, we have sought to preserve and protect the world’s spiritual wisdom so that humanity may forever have access to the knowledge upon which to build a sustainable future, one that celebrates and heals the earth.

Our Paper Stewardship Policy

Our commitment

We are committed to the responsible use of natural resources. We are concerned about the future of the world’s remaining endangered forests and the environmental impacts of paper production. We are committed to implementing policies that will advance best practices within the book and paper industries. We are aware of the impact that paper production and consumption has on the environment and on human health. We are committed to energetically working with our printers to find a practicable way to maximize the use of papers that are recycled and/or sustainably and responsibly produced.

Our business niche

Practically all of our books stay in print perpetually and after 35 years of publishing we have over 1,200 books in our list. The great majority of our titles make up what is known as a “long tail” with small print runs. Keeping these backlist books in print is crucial to our business and is one of the ways in which our publishing company is unique. We believe that books are meant to last a lifetime or longer and that they should stay available beyond just one or two years.

To make this strategy profitable we have developed a special relationship with one printer in particular, to whom we have guaranteed most of our new book printings in exchange for rock bottom pricing on the very small printings of the long tail. It is a business relationship built on close communication, mutual loyalty, and care, and it is important to note that, for the above reasons, there are limits on our ability to use our print volume, such as it is, to squeeze better pricing from printers.

Our paper usage

Paper is a significant expense in our business and it must be sourced and managed in an economically responsible way. We publish 68 new or revised books each year. We generally reprint 150 to 175 of our previously published titles each year, with small print quantities. Thus our typical per-unit print costs are necessarily high and there is little room to absorb extraneous costs.

Recycled sheets

It is our desire to use FSC certified papers in our books, and we currently do so in some cases. After extensive exploration we have found that recycled sheets of acceptable quality invariably cost more. Consequently, we print only occasionally on PCW sheets, but we are committed to constantly working with our printers to offer us an economically viable plan for increasing our use of PCW, FSC-certified papers going forward. We will press our printers every half-year (when our season of new releases is out for bid) to offer FSC papers at an equivalent quality and price. This effort will likely take time and patience but we trust that the increased demand will benefit the campaign for paper sourced from the highest standards.

We have established the following policy goals.

We aim to attain a standard in which our paper use has no negative environmental or social impact and whose production will ultimately be a part of a process that respects the earth. Where possible, we pledge to use our purchasing decisions as a catalyst to stimulate environmentally responsible paper production.

As mentioned above, there are limits imposed on us by the cost and quality of environmentally responsible paper. While we acknowledge that there are market factors we cannot completely control, we are committed to doing all we can to continually use the best possible paper and will work to maximize the sustainability of our paper and production processes in the following ways:

- by eliminating paper that may contain fiber from endangered forests

- by using fiber efficiently and economically

- by procuring environmentally responsible paper

- by encouraging cleaner production processes

- by actively engaging in reforestation

- by engaging in best practices in our office

- by communicating our goals and achievements

1. Eliminating paper that may contain fiber from endangered forests

Old growth and endangered forests should not be a source of any fiber for paper production. We make every effort to eliminate the use of papers that may contain such fibers. This applies to all our books whether printed and bound in the U.S., Canada, or other countries, such as the small percentage of our printing done in India or China.

2. Using fiber economically and efficiently

Less pressure is placed on forests when less fiber is used. In addition, using less fiber is more cost effective as it results in a reduction of freight transportation and distribution costs. We keep our fiber use to a minimum in the following ways.

- We set very tight print runs. It is a rare printing that will not sell out in two years.

- We almost never put a book out of print. Our focus on the enduring quality of the content means we typically have a perpetual market for every title. Therefore, our books are not remaindered and there is no need to have them pulped or recycled.

- Our returned books are never discarded. Books in mint condition are put back in stock for sales and scuffed books are sold at discounted prices directly to readers and to used booksellers.

- We are using a lighter basis weight in our books whenever possible. We have switched from 60# paper to 55# or 50# paper in most of our new books, and as titles move to smaller print runs we use 45# paper.

- In our office, we use recycled paper (100% PCW), print on both sides of the sheets, and recycle any paper waste.

- We are urging our customers to accept our catalogs and promotional materials in paperless form, via email or our website. For the foreseeable future we will still require some printed catalogs, but in 2010 we began printing these on sheets containing at least 30% PCW fibers, despite the cost premium. In 2010, almost half of our catalogs and promotional materials were printed on 30% PCW, FSC-certified sheets; in 2011, that percentage will increase to 95%. Our goal is for 100% of our catalogs and promotional materials to be printed on 30% PCW, FSC-certified sheets and with greater percentages of PCW fiber, as the economics allow.

3. Procuring environmentally responsible paper

For our book printing, we have a preference for paper that comes from responsibly managed forests. Since virtually none of our books enter the waste stream, using fibers that come from rightly managed forests is a best practice. Thus, we use FSC-certified or SFI-certified fiber whenever possible and work to promote harvesting processes that meet FSC or SFI standards through communications with our supply chain. In 2010, we printed 30% of our new and reprinted books on FSC- or SFI-certified sheets. In 2011, we will increase that to 50% and in 2012 to 60%. Our goal is to use only certified sheets for all books, new and reprinted, by 2016.

Virtually all of our books are published with a view to going into our reader’s libraries. We expect them to last a lifetime and even be passed on to the next generation. We pledge to print any book designed for a limited lifespan—almanacs, books that need to be frequently updated, or any book that has the potential of entering the waste stream—on sheets with PCW content despite the present premium.

4. Encouraging cleaner production processes

Inner Traditions is committed to researching and, when possible, implementing ways of addressing the negative environmental and health impacts of chlorine, ink and coated paper in the printing process.

- Chlorine compounds are commonly used to whiten paper, but they contaminate the soil, water, and food supply. We aim to use processes that whiten paper without any chlorine.

- Petroleum-based inks are harmful to the environment and human health. We are exploring printing with soy or vegetable inks going forward. As with PCW paper, cost premiums add financial pressure to our decisions but we recognize that working with our printers increases demand and is likely to help prices fall.

- Uncoated paper is the most environmentally responsible choice, since coated paper can generate emissions and uses a great deal of energy. The vast majority of our books use uncoated sheets. When coated sheets are required to produce suitable quality (in art books or color inserts, for example), we pledge to seek sheets that avoid a sealing coat and that use a VOC-free coating, to the extent it is economically feasible.

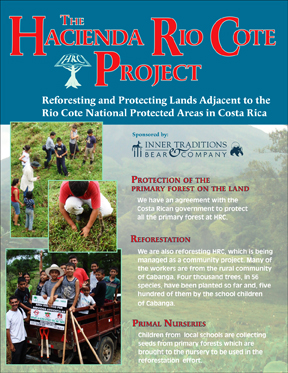

5. Actively engaging in reforestation

In the summer of 2007, Inner Traditions created the Hacienda Rio Coté project (HRC). We purchased two farms consisting of primary rain forest and pasture, adjacent to the Rio Coté National Forest in Costa Rica. The primary forest has been put under contract with the Costa Rican Government to preserve it in perpetuity. On the pasture we have planted over 6,000 trees to date and continue to plant more each year. In addition to restoration and protection of the primary forest and watershed, HRC helps to offset our carbon footprint. It provides habitat for animals and insects and creates livelihoods and economic sustainability in the local community. Unique for a project such as this, the HRC project also includes rotating herds of ruminants across pastures with perennial grasses, a practice at the cutting edge of carbon sequestering and which also increases fertility of the pasture that will remain as farmland.

The HRC project is completely funded, supported, and administered by Inner Traditions. Local school children have participated, helping to gather seedlings from the primary forest to begin the cultivation of new trees in a nearby nursery. From there, members of our company have worked side-by-side with other Costa Rican community members to plant the trees.

6. Engaging in best practices in our offices

Inner Traditions • Bear & Company proudly promotes a family-friendly workplace supportive of the needs of parents raising young children by offering flexible schedules and actively promoting the health and well being of the staff. Inside our offices you’ll find some employees who’ve been on board for more than 20 years (since we moved to rural Vermont), and whose own children have, after reaching adulthood, accepted positions at Inner Traditions as well. We operate out of a nineteenth-century farmhouse situated in downtown Rochester, a quiet village nestled in the Green Mountains of central Vermont. Many employees live within walking or biking distance of the office. We purchase foods communally via a natural foods coop that delivers to the company’s door and acquire other fresh foods through Vermont Roots, a “shop local” program. Next door to our office building is a company-owned building housing a homeopathic clinic and a gym, which employees are free to use anytime of the day. Staff members are also encouraged to attend strength-training and yoga classes paid for in part by the company.

In 2009 we installed solar panels on our offices utilizing every southern-facing rooftop. Our system can generate 13,000 kWhs per year, offsetting the production of over 22,000 pounds of carbon. All copy paper we use is made with 100% PCW recycled sheets and we use both sides of the sheets before returning them for recycling. We clean only with eco-friendly products.

Inner Traditions is an active participant in our community. We host Rochester’s Internet service; maintain a back-up generator available to the town during emergencies; provide a yearly scholarship to Rochester High School graduating students; and provide financial and in-kind support to local organizations including the library and theater group.

7. Communicating goals and achievements

There are numerous benefits in declaring and promoting our environmental stewardship policy with our readers/customers. Inner Traditions pledges to publicly promote our environmental commitment by displaying our certification logo and/or environmental audit and PCW content on our books and advertisements and by placing our commitment to the environment on our website. We will update progress on our research and policy initiatives annually or more frequently where breakthroughs are achieved. Responsibility for this lies with our Sales & Marketing Department, presently with Rob Meadows, Director of Content and Consumer Sales.

We welcome comments or dialogue with any publisher that has worked towards similar goals and might have specific insights or recommendations to share. Please contact Rob Meadows at robm [at] InnerTraditions.com.

A Radical Call for the Elimination of Tree Fibers in Paper Production. Over 200 years ago, Benjamin Franklin established a mill that produced hemp paper. Thomas Jefferson used just such paper when he wrote the first draft of the Declaration of Independence. During World War II, our government encouraged the production of hemp for its various benefits including as a source of fiber in paper and clothing. In November of 1995, we began exploring the benefits of using hemp fiber as a substitute to trees in making paper. We imported hemp sheets from China for our title The Great Book of Hemp in an effort to realize our dream of printing on tree-free papers. Unfortunately we were unable to bring the initiative to conclusion because the paper jammed in the offset presses. We ended up having it cut up and made into note pads, which were used in the office for many years.

Interestingly, France in recent years has been using hemp fibers to produce bibles that require very thin sheets of paper for which hemp paper is better suited as the fibers are much longer and stronger.

Our dream is that the publishing industry might eliminate the use of wood fiber altogether and turn to hemp. Hemp has superior fibers and can be grown on poor land. Hemp does not require the toxic chemicals that are used in processing paper, including recycled paper. The oil from the hemp seeds could be used to generate electricity to run the paper mills. Ultimately, paper made from hemp can be shredded and used as mulch and in compost. The ideal paper mill of the future would have its own ongoing and renewable source of hemp fibers grown adjacent to the plant thus reducing the cost of transportation. Unfortunately, at this time there is no significant manufacturing of hemp paper in the United States, but as soon as it is fully available, Inner Traditions will begin working on making our hemp dream a reality.